Warehouse pest management is a critical part of maintaining operations in any storage facility, distribution center, or warehouse that handles products. The importance of pest control in these environments extends beyond just removing visible pests; it is about creating an audit-ready, compliant framework that ensures safety, quality, and efficiency across operations. Warehouse pest management must align with health and safety regulations like FSMA (Food Safety Modernization Act) or local health standards, which require ongoing monitoring, documentation, and proactive pest prevention strategies. This article will explore the importance of maintaining an audit-ready pest management system, solutions to prevent pest entry, strategies for dealing with specific pest types, and the significant ROI of a solid pest control plan.

The Importance of an “Audit-Ready” Framework in Warehouse Pest Management

Maintaining an “Audit-Ready” framework is essential for compliance with both local and international health regulations. Whether your warehouse is handling food, pharmaceuticals, or other sensitive goods, pest control cannot be treated as a one-time fix. A system of continuous documentation, regular pest sighting logs, and trend reports should be part of the day-to-day operations. This framework not only protects your inventory but also demonstrates due diligence to auditors, clients, and regulators.

Key elements of an “Audit-Ready” framework include:

- Pest Sightings Logs: Keeping detailed logs of any pest sightings, whether they’re rodents, insects, or birds. This log should include date, time, location, type of pest, and corrective actions taken.

- Trend Reports: Analyzing pest sighting logs over time to identify patterns. Trend reports help pinpoint areas where pest activity is most common and can indicate vulnerabilities that need addressing.

- Integrated Pest Management (IPM): IPM is a preventive approach that focuses on long-term pest control rather than just eliminating pests after they appear. It involves understanding pest biology, preventing infestations, and using environmentally-friendly practices to minimize pesticide use.

All of these elements help you maintain compliance with regulations such as FSMA, HACCP, or local health standards, which require stringent monitoring and documentation to ensure food and product safety.

Barriers to Pest Entry: Zoning and Physical Barriers

One of the most crucial elements of warehouse pest management is ensuring that pests cannot easily enter the facility. This requires a focus on physical barriers and zoning, which helps to manage and contain pests before they cause damage.

The 18-Inch Sanitation Border

The 18-inch sanitation border is a basic but essential barrier that helps prevent pests from accessing your warehouse. This space—usually along walls or floors—should be kept clear of debris, trash, and any potential food sources for pests. The area should be regularly cleaned and maintained to ensure pests do not have an easy path into the building.

Loading Docks: A Vulnerable Point

Loading docks are high-risk areas for pest entry because they are frequently open during deliveries and shipments. The constant in-and-out of goods creates opportunities for pests to enter, often unnoticed. To mitigate this, warehouses should focus on sealing loading docks with physical barriers, including:

- Air Curtains: Air curtains are devices installed above doors that create an invisible barrier of air, preventing pests from entering when the doors are open.

- Brush Seals: Installing brush seals on doors and loading dock openings can prevent rodents, insects, and other pests from sneaking through cracks and gaps in the building.

- The “Three-Door” Rule: This rule advocates for having a sequence of doors or barriers that pests must pass through to enter the building. Each door should open only once the previous one has fully closed to prevent pests from slipping through.

When physical barriers like these are combined with a regular cleaning schedule, pest entry can be significantly reduced.

Types of Pests in Warehouses and Their Specific Management Strategies

Warehouses face several types of pests, each requiring a different approach to control and prevention. Let’s look at three of the most common pest problems in warehouse environments:

Stored Product Pests (SPPs)

Stored product pests, or SPPs, are one of the most significant threats to warehouses that store food or agricultural products. These pests include weevils, beetles, moths, and other insects that can damage goods and contaminate products with their larvae or droppings.

One effective strategy for managing SPPs is pheromone monitoring, which involves using pheromone traps to track pest activity and pinpoint areas of high infestation. This allows pest control teams to focus their efforts on the affected areas and monitor pest populations over time.

Rodents

Rodents, including rats and mice, are common in warehouses, especially in areas that store food or other consumables. They not only contaminate goods but also chew through electrical wiring and insulation, which can lead to costly damage.

Rodent control in warehouses typically includes:

- Proper Trap Placement: Traps should be placed along walls and near entrances where rodents are most likely to travel. The use of bait stations can also help keep rodents at bay.

- Sealing Entry Points: Inspect the warehouse for any cracks, gaps, or holes where rodents can enter. Seal these areas to limit access.

- Regular Monitoring: Place traps or monitoring stations around the warehouse and perform regular inspections to ensure that rodents are not active.

Birds

Birds, especially pigeons, are common in warehouses due to their easy access to high structures and ledges. They can damage property, contaminate goods, and create a mess that can lead to health hazards.

To prevent bird infestations, warehouses should consider the following:

- Netting: Netting can be installed to block birds from nesting in open areas or around vents and windows.

- Laser Deterrents: Laser technology can be used to disrupt the birds’ roosting behavior, preventing them from settling in the warehouse.

- Visual Deterrents: Hanging shiny objects, reflective tapes, or predator decoys can deter birds from entering the warehouse.

Cost-Benefit of Pest Prevention vs. Infestation

The cost of pest prevention is often much lower than the hidden costs of a full-scale infestation. When pest control is delayed, the damage can extend beyond just product loss. Other hidden costs include:

- Discarded Stock: Infested goods may need to be discarded, leading to significant inventory loss.

- Brand Damage: Customers and suppliers may lose trust in your facility if pests are found.

- Contract Loss: Companies with pest problems risk losing business contracts, especially in industries like food, healthcare, and pharmaceuticals.

- Increased Labor Costs: Employees may need to perform additional cleaning and sanitation efforts.

Investing in proactive pest control and management provides a return on investment (ROI) by preventing these costs and ensuring smooth operations. It also maintains the reputation and credibility of the warehouse.

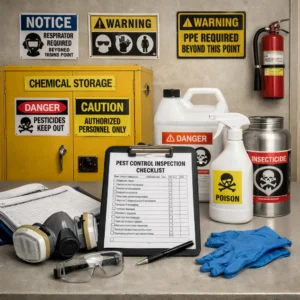

Red Flag Checklist for Warehouse Managers

To make pest management easier on the floor, warehouse managers can use a red flag checklist to quickly identify and act on potential issues. Here’s a sample checklist to help:

- Are there any visible signs of pests (droppings, gnaw marks, nests, etc.)?

- Are traps and pheromone monitors being checked regularly?

- Have air curtains, brush seals, or other physical barriers been inspected?

- Is there an ongoing sanitation issue (food crumbs, spilled items, clutter)?

- Are there gaps or cracks in walls, doors, or windows that pests can enter through?

- Is the 18-inch sanitation border clear and maintained?

- Is bird netting or deterrent technology in place for high-risk areas?

Having a checklist like this can help warehouse managers proactively address pest problems before they escalate into full-scale infestations.

When to Call for Professional Warehouse Pest Management

While many preventive measures can be handled in-house, some situations require professional pest control services. Expert intervention is especially necessary when:

- The infestation exceeds what can be managed with DIY efforts

- Pests are found in sensitive areas (food storage, pharmaceuticals)

- The building has structural damage or entry points that are difficult to identify

- There is a need for specialized equipment, such as pheromone traps or laser deterrents

- Existing measures aren’t yielding results, indicating deeper problems

Conclusion

Warehouse pest management is about much more than killing pests—it’s about preventing them, maintaining a safe and healthy environment, and protecting your inventory, reputation, and long-term profitability. By following best practices like maintaining an audit-ready framework, addressing entry points, using physical barriers, and relying on expert pest control, warehouses can minimize the risk of infestations and reduce their overall costs.

At First Station Pest Control Services, we offer comprehensive pest control solutions for warehouses in Sharjah, ensuring compliance, safety, and long-term pest prevention. If you are unsure whether professional intervention is needed or want to discuss proactive options, feel free to contact us through the WhatsApp or Call button above to talk to our team.